Top-quality profiles that effectively meet real needs

As the official distributor in Hungary, our aim is to help you choose the profile that is truly appropriate for the intended function, as well as the dynamic and the static load of the industrial floor.

To handle the increasing industrial floor loads without any problems, conventional steel profiles in most cases do not offer acceptable solutions, or only at a considerable compromise.

The steel profiles available in the HCJ range actively help to achieve the desired dynamic as well as static load transfer. Choosing the right profiles can not only provide technical benefits, but can also contribute to faster, safer traffic throughout the life of the floor.

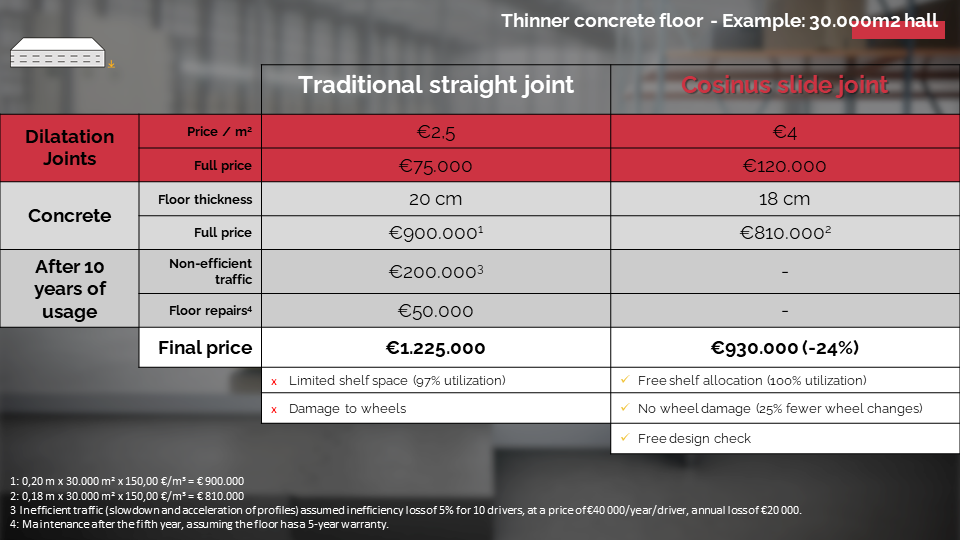

Enjoy the benefits of our premium HCJ dilatation joints by reducing industrial floor thickness – while increasing longevity and quality.

Dilatation Profiles

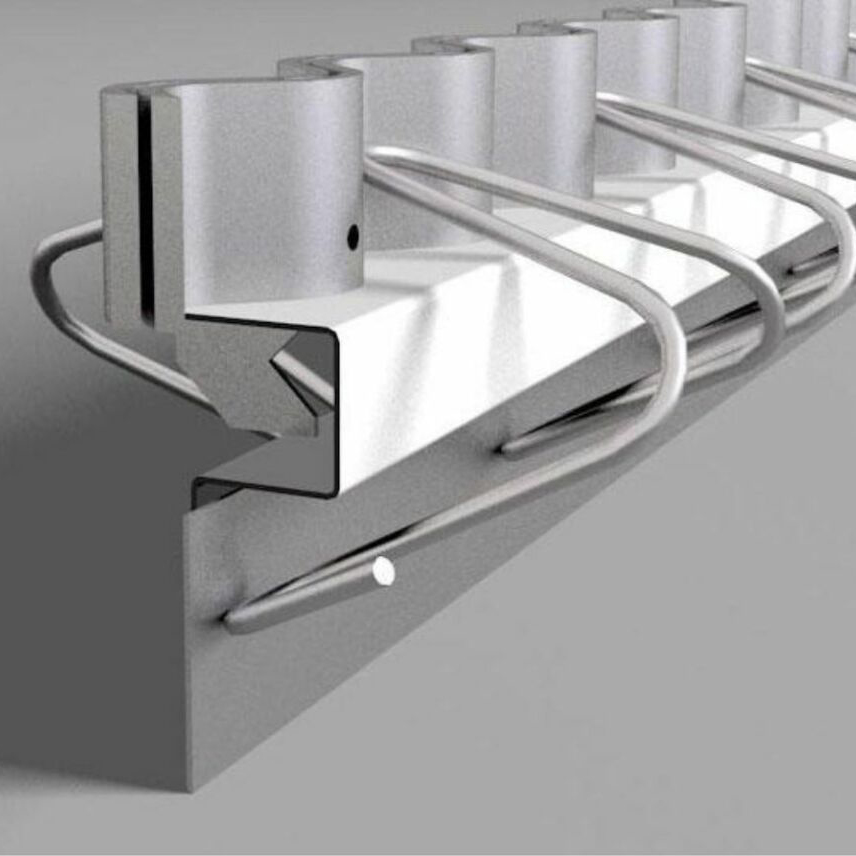

Cosinus Slide Profile

The top-quality Cosinus Slide® steel profile is clearly HCJ’s flagship product, able to meet all the demands and quality requirements that arise.

The Cosinus Slide® profile is recommended for all customers looking for a high quality, uncompromising dilatation profile, that ensures maximum load from traffic.

Dilatation Profiles

E-Slide Profile

E-slide steel profiles are the perfect solution in cases where the high-tech Cosinus Slide is not required.

The main advantage of E-slide profiles is that, in addition to their outstanding quality, they are also extremely economical, offering significantly better performance in all parameters at a price close to that of conventional straight profiles.

Dilatation Profiles

Omega 3mm Expansion Joint Profile for Outdoors

Omega 3mm is one of the highest quality outdoor expansion profiles available, despite its low price, and can meet the needs of the application for a long time. Choose Omega 3mm, the perfect outdoor expansion profile to achieve the right quality.

Watch our webinar about the innovative HCJ joints

The Cosinus, E-Slide, E-Straight, and Omega 3mm profiles produced by HCJ, described above, are matched profiles that can be used in a system: on request, we will carry out the structural calculations that justify their applicability, free of charge, provided that the load data are available.