How do you make reliable, cost-efficient industrial concrete floors?

What is the goal of the industrial floor?

While creating warehouses or other logistics centers, our goal is not only to make something nice-looking. You want to possess a building (warehouse, logistics center, factory) that delivers the goals of your organization, whether it is satisfying your renters, or serving your logistics processes efficiently and smoothly. Therefore, every step needs special attention, even the industrial concrete floor.

The industrial floor is “just” a small component of this complex system, but it serves as a basis for all work processes. Industrial floors are crucial elements in a sense that if they cannot serve its intended purposes, it will be a constant problem, making any work harder and less efficient.

To construct a perfect industrial concrete floor for its intended purposes, it should go like “once we built it, now we can forget that it is even there”, because it will not cause any troubles, and will work just fine for the upcoming years.

What makes our industrial floors unproblematic?

Your industrial concrete floor will only be truly unproblematic and shock-free, if it works so fine you do not even have the idea of it being there. It serves us so naturally like our legs and joints, which helps us to walk, or our eyes to see.

It is so natural that these parts of our body works, that neither we think about seeing with our actual eyes, nor about how we are going to lift our legs to walk, because these things just work as intended. And that is how it should be.

We can compare a poorly designed or constructed industrial concrete floor with our legs if we have some problems with them. Suddenly, we think about them once the problems occur.

Now it is like an obstacle, because we cannot do what we really want to. Moreover, fixing the problem (inspection, doctors, surgery, rehabilitation, etc.) costs a lot of time and money, diverting our attention from the things we want to do with them. Naturally, as almost everything, these problems could have been avoided previously.

An industrial concrete floor is not that complicated as the human body is, but there are at least 12 “problematic fields” – like walking in the case of humans – which needs highlighted attention.

Good news is that with Allen Face Europe, we design and engineer industrial floors in a way that it is going to be “forgettable”, meaning unproblematic and well-working.

How should we implement the concrete steel joints regarding industrial floors?

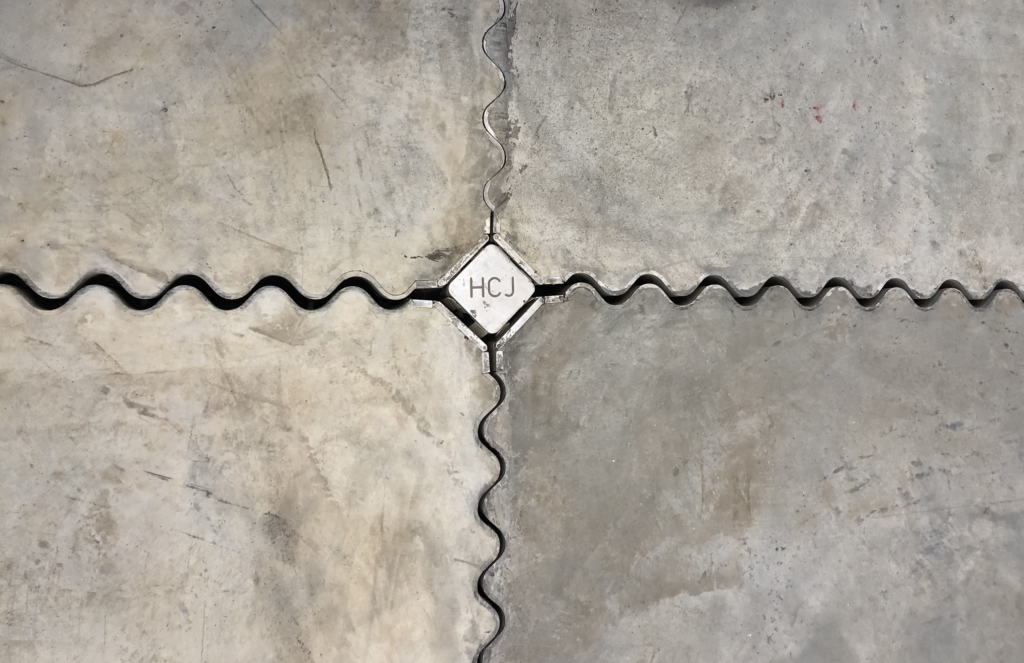

One of the critical areas concerning industrial concrete floors can be found in the topic of concrete steel joints.

The industrial floor for modern warehouses, logistics centers, and factories are mostly built with the help of panels. These units range from 400 to 1000 square meters. As a whole, these will serve as the final industrial floor for any purposes.

These panels are bordered by the previously mentioned concrete steel joints, and their intended roles are significant. They transfer the weight from one panel to another, whether it is the dynamic weight of the forklifts, or the static weight of the shelves.

As indicated by their names, the steel concrete joints truly are the joints of the industrial concrete floors. Similarity can once again be found when compared to the human body, since we will only have problems with our joints if we overload them, or do not give them the necessary caring.

The joints of the industrial concrete floors

It is up to us to make the best decision in the case of the concrete joints for our industrial floor.

It is crucial what principles we consider while choosing from all the available concrete joints from the market, and it is also significant how precisely and carefully we implement them into the industrial floor itself.

The effects of a poorly chosen concrete joint profile

Unfortunately, according to my experiences, making the best decision is still far away from ideal. We can see its consequences on the following pictures:

These are far from being just “old” industrial concrete floors, since they were built 5 years ago.

I do not think that the owner is happy that the forklifts have to almost stop completely to get over the concrete joint profiles.

They are not happy neither when they have to pay for a new set of wheels for the forklifts.

But also, the warranty of the forklifts can perish because of the conditions of the concrete industrial floor.

Moreover, it is going to be really hard to deal with the constant complaints from the leader of the warehouse, or from the drivers of the forklifts directly. Not to mention what health related issues can appear in the case of the drivers.

The consequences of a poorly designed industrial floor

It is justifiable to feel bitterness once the costs of the repair are revealed. Furthermore, if the warehouse was already working, you would have to move certain parts, which results in even more extra work and costs just to fix your industrial floor.

Needless to say, these costs would be better spent on new investments and projects.

Moreover, it is a true challenge to find reliable, experienced specialists that bear the responsibility of a well-working industrial floor.

What is one of the most frequent problems of concrete industrial floors?

The issues are mostly caused by not choosing the adequate concrete joint for the industrial floors.

During any projects, all costs should be considered. They should be immediately paid, and we should always save on them if possible.

At the same time, we always pay the highest amount for those “savings”, which result in extra costs once the warehouse/logistics center/factory functions, and its fixing is even harder than prevention would have been in the first place, during the construction.

No one can expect from the owners/project managers to be specialists on every field regarding the construction works. Hence they need professionals to prevent future problems, and to ease their own jobs as well.

Going back to the case I mentioned previously, which can be seen on the pictures, a poor decision was made regarding the concrete joint profiles. They opted for the cheaper solution rather than choosing the long-lasting, quality one. Its effects are visible on the industrial concrete floor.

How can we get the functionally perfect concrete industrial floor?

By being careful, and with the assistance from specialists, you can get the concrete joints which will perfectly serve your needs. Although you have to consider that it is not always the cheapest solution, but it will be in the long run, since no (or much less) maintenance will be needed, because we design and engineer industrial concrete floors for 40-50 years.

Although we have to note that this is the perspective of the owner, which cannot be expected from the executor.

In our opinion, only an independent industrial floor specialist can consider every perspective regarding the floor, and can suggest the best concrete joint, customized for your needs.

Concrete joints are not the only solutions for the frequent problems

Now that our concrete joints will withstand the weights, we will get a healthy industrial concrete floor that is going to function as it was intended for years and decades.

But at the same time, the cracks on the pictures can only be “achieved” if other factors were present, it was not only the fault of the poorly chosen concrete joint profiles.

One of the reasons can also be that once the concrete joints are chosen right, they can still be implemented into the industrial concrete floor wrong. Naturally, this problem can be avoided if industrial floor specialists supervise the construction processes.

How to achieve a truly long-lasting industrial floor?

This requires entrusting an independent industrial floor contractor with their help, who possesses the needed experience and the appropriate insights from designing the thickness and other details of the industrial floor, through the controlled construction and the accuracy of the floor levelness, until finally knowing certain functions (whether random or controlled traffic uses the industrial floor for instance) and special operations (grinding the industrial floor).

This way, you do not need to be a specialist on the field of industrial floors, so you can pay attention to what really moves your organization ahead.

Our company, Allen Face Europe Ltd can not only suggest you the perfect concrete joints for your needs (HCJ concrete joints), but also assure the quality of your industrial concrete floor on multiple fields, such as floor flatness and floor levelness, and we can also physically provide solutions to these problems with VNA grinding or spot grinding.

You can decide whether you need our services or not by signing up for our online free preliminary consultation, in which we can talk about the needs and requirements of your industrial concrete floor, and find the best, customized solutions, just for you.

Miklós Vass

Industrial floor specialist, Allen Face Europe Ltd